When it comes to buying a Custom LEGO Minifigure, you want to be able to make an informed decision about what you are buying. There are lots of different ways in which a LEGO minifigure can be customised – including decals, paint applications and more. In this article we wanted to take the time to compare two of the more common printing methods which you are likely to encounter within the Custom LEGO Minifigure world – UV printing, and Pad Printing. Both types of printing can achieve incredible results for your minifigures – but there are also some slight pros and cons which are prevalent for each. Let’s start off by exploring UV printing!

For talking about UV printing it seems fitting to include our friends at Leyilebrick – who use this form of printing on many of their custom minifigures. UV Printing is essentially digital printing using ultraviolent light which allows ink to either be dried or cured as soon as it hits a surface – which, in this case, would be the LEGO Minifigure’s torso. UV Printing has a range of broadly applicable positives – including the fact that it is beneficial for the environment. UV printing doesn’t release any solvents or nasty chemicals into the air – meaning it won’t hurt the environment. Another big advantage is the fact that UV printing can be done on non-porous materials, meaning different elements could be incorporated into a LEGO minifigure’s design. Applying this logic more specifically to LEGO, the ability to print on anything, anywhere means that it should be easier to print details on every component of a LEGO minifigure.

However, there are a couple of negatives to consider with UV printing in comparison. Firstly, there is the fact that UV printing is an expensive investment for custom LEGO Minifigure designers. This can mean that if an individual is investing in the technology as their main source of income, then the additional costs may be fed down into the prices of their custom minifigures – meaning that we, as consumers, will have to pay more money to get our hands on the custom LEGO minifigures which we want. It is also worth noting that the finish of UV printing can be a little bit more glossy than traditional LEGO minifigures. Whilst this isn’t noticeable in a low-light environment, it is worth noting that this may show the distinction between a custom and non-custom minifigure in a well-lit environment. The last thing to consider is texture, too – with UV printing sometimes leaving a more 3-Dimensional feel to the minifigure torso. This is a pretty minimal negative in the grand scheme of things – but is still something you may want to consider.

Overall, UV printing is a great way to get some custom minifigures – but be prepared to pay a higher cost. This is something which you will also see with pad printing – but it’s important to note that, as with anything, you really are paying for quality when it comes to custom LEGO minifigures!

Pad Printing, in contrast, is a process which uses press devices to transfer ink onto a surface – again, in this case, a minifigure. A Silicone pad will feature the design which you which to transfer onto the object in question, and this will then press the design into place on the minifigure through the use of ink. A big advantage with pad printing (as found here) is the fact that the printing can adapt to whichever surface it is being placed on. This means that things like arm-printing on a LEGO minifigure can have a better wrap-around effect then you would be able to achieve from UV Printing. Another element worth noting in this article in particular is the fact that Pad Printing is higher resolution – meaning designs are sharper and clearer. If you’ve ever received a custom minifigure which has a slight blur to the lines or the design then you will be aware of how much that can ruin the overall aesthetic, so pad printing is really beneficial in avoiding that from happening. Lastly – and, arguably, most importantly – this is the technique that LEGO uses! If you want a custom minifigure which is going to come close to the designs which LEGO uses then pad printing is pretty much the way to go – matching the quality and style of LEGO minifigures perfectly. This can really help to blend your minifigures in to your LEGO collections – allowing them to not stand out from the crowd, which is sometimes more important!

It’s worth noting there are a couple of disadvantages here which may influence on your purchasing experience. The first is, again, cost. A press machine may need multiple pads to tackle specific patterns, and all of this requires additional investment in resources. Combine this with the fact that the dying process with pad printing takes time, and it means that customizers using pad printing not only have to account for the cost of their machinery and additional pads, but they also have to account for drying time and storage space, too. This is also something to consider when it comes to commissioning one of your own custom minifigures – as if you need a multitude of figures quickly for an event, then pad printing may not be the way to go as it may not be possible to develop multiple custom minifigures in a short period of time. It is worth noting that once a UV printing machine’s cost has been covered, customizers can begin to minimise their costs – whereas the pad printing method will have a constant additional time cost which needs to be accounted for in product pricing.

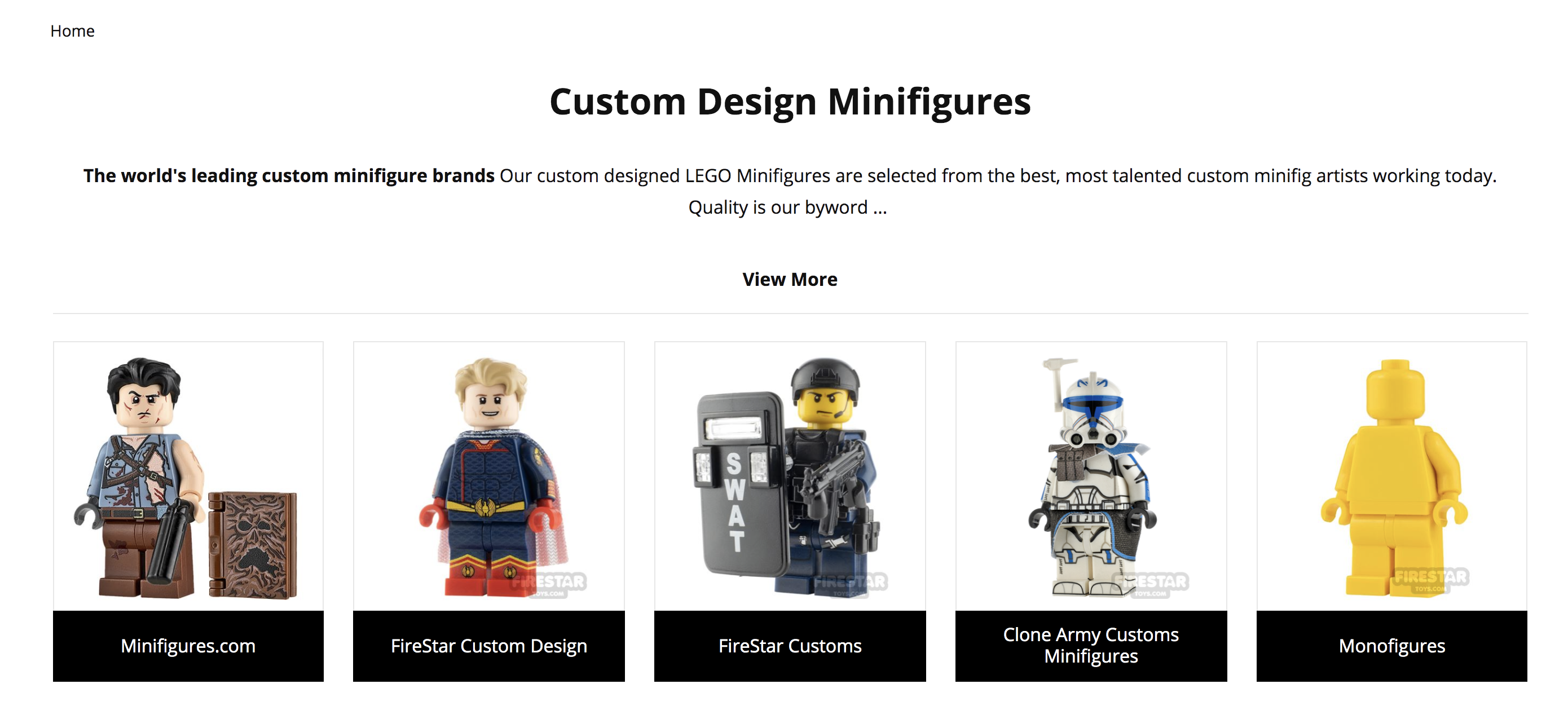

(You can view the whole range of custom minifigures on Firestar Toys by clicking the above image)

So, what’s the conclusion? It’s simple – both have their value, and both can produce you incredible custom minifigures. I think it is worth noting that UV Printing technology has really expanded in recent years, too. I’ve received minifigures using UV technology which blend seamlessly with my LEGO minifigures, meaning that the necessity to pay top-of-the-line pad printing prices isn’t as prevalent as it perhaps once was. With that said, there is definitely still a value in pad printing – allowing some fantastic results for custom minifigures which are really eye-catching and high-quality. Depending on your timeframe and what you’re looking for, both options provide you with a great chance to get your hands on some unique minifigures which will allow you to expand your collection.

That’s my thoughts on these printing methods – but I’d welcome your input in the comments down below, too! Let me know if you have a preferred printing method for your custom minifigures, and why it is that you prefer that type of minifigure.

Don’t forget that pad printing needs less ink than UV printers! It’s a tiny bit, but the 3D effect in UV does require extra ink, which is especially bad for the environment. But these savings depend hugely on the amount of figures needed. Also, the UV ink expires more easily.

Another plus of pad printing, is that it allows for some metallic colors, which are not possible with UV. By contrast, with UV it is easier to do gradients.

Thanks for the nice article! 🙂

Also, don’t forget that pad printing needs a bit less ink than UV printers per fig. It’s a tiny bit, but the 3D effect in UV does require extra ink, which is especially bad for the environment. But these savings depend hugely on the amount of figures needed. Also, the UV ink expires more easily.

Another plus of pad printing, is that it allows for some metallic colors, which are not possible with UV. By contrast, with UV it is easier to do gradients.